As the green movement makes its way toward the mainstream, more and more industries are taking a hard look at how their practices impact the health of both humans and the environment. The foodservice business is no exception—especially when it comes to the design, construction and remodeling of its facilities, stores, kitchens, and dining spaces. In fact, the entire building sector is under more pressure than ever to reduce their footprint and embrace more sustainable design and construction conventions.

What does this mean for foodservice design?

Well, for starters, the foodservice industry and its design consultants, architects, in-house designers and builders will begin to embrace (or in some cases concede to) the fact that the future is green. Little by little, at varying intervals and speeds, different green practices and priorities will inch their way from the fringe to the forefront.

Creating greener designs doesn’t have to be an all-or-nothing approach. Foodservice operators and their designers can start by incorporating a few “quick wins” and throttle their approach up or down based on project goals and comfort level.

Whatever the case, they can make strides toward a greener tomorrow by evaluating three important areas of a design:

- Material Analysis

- Spatial Planning

- Equipment Selection

Material Analysis

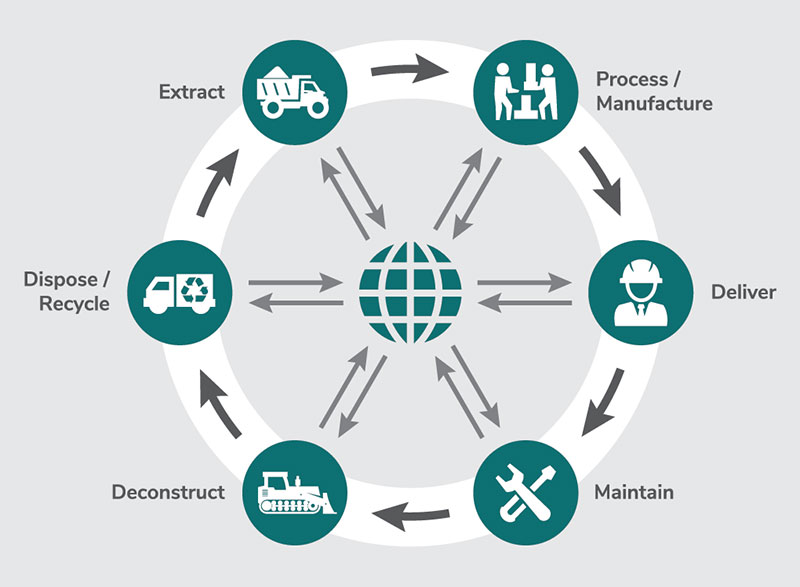

While there’s no one-size-fits-all formula to determine the ideal eco-friendly material for a specific application, looking at the whole life-cycle environmental impact of building materials can help.

This “cradle to grave” approach involves evaluating how a building material contributes to greenhouse gas production, air quality, water consumption and the depletion of resources. However, it delves deeper, considering the energy consumption implications at each and every touchpoint.

Life-Cycle Assessments

Life-cycle assessments (LCAs) are a methodology that’s been used since the 1960s to assess and critique the environmental impacts associated across all life stages of a material, product or practice.

What materials are green?

The above considerations beg the question of which materials are more eco-friendly than others. Of course, no material is perfect. However, some will score higher on the sustainability and conservation scale than others. Knowing what to look for can help design professionals and foodservice organizations gauge the potential impact of the materials they prioritize.

Considerations for the evaluation and selection of materials:

- Durable enough to stand the test of time

- Recyclable

- Renewable (e.g., wood, stone, clay, bamboo)

- Available locally to eliminate long-haul transport

- Responsibly harvested

- Sourced from an eco-conscious supplier

- Recycled or repurposed from architectural salvage

- Non-toxic

- Non-synthetic

- Free of volatile organic compounds (VOCs)

Be wary of misleading claims! Just like with food, the term “natural” is often used by suppliers and distributors to sell or market a material as healthier for people and the environment. But, just because a material is natural doesn’t make it green.

Spatial Planning

Come time for the schematic and design development phases of a project, design professionals must consider how their use of space impacts the efficiency and sustainability of a room, a group of rooms or an entire building. Luckily, most designers are already doing this. In efforts to drive long-term cost savings for clients or their own companies, they are also—intentionally or unintentionally—designing foodservice spaces that use less energy.

Increase circulation

Part of these efforts involve implementing an efficient heating, ventilation and air conditioning (HVAC) strategy. Since cost and energy savings are largely dependent on how well a room can circulate air and maintain comfortable and safe temperatures, design professionals need to stay up to speed on the latest approaches for meeting their HVAC goals.

Maximize natural light and ventilation

One tried-and-true method is daylighting, where designers strategically position reflective surfaces, windows, skylights and other openings to maximize natural light and temperature control. In addition to windows, designers should consider other natural ventilation techniques, such as open-air dining areas with garage doors that operators can open and close depending on the weather.

Strategically position equipment

At the most basic level, designers should position equipment so it doesn’t have to work harder and consume more energy than necessary. They can’t just pop a piece of equipment anywhere. They need to think through how people will use it, access it and service it — as well as where within the foodservice space it will create the most energy efficiencies.

When evaluating where to position equipment, designers should keep these best practices in mind:

- Distance heat-producing equipment from refrigerated equipment and drafty doors.

- Position self-service equipment, such as beverage cases and heated display cases, so operators and customers can easily access them without leaving doors open for extended periods of time.

- Position equipment so it’s conveniently located, but not exposed to excess wear and tear that could lead to premature servicing or replacement.

- Situate equipment where staff and technicians can easily clean or service unit components because well-maintained equipment will always run more efficiently.

Equipment Selection

Aside from determining where equipment will live within a plan, design professionals need to think about what equipment to recommend for the job. Not all equipment is created equal. Some will use more resources like energy, fuel and water. Others will tread much lighter on the earth — helping operators conserve resources and create healthier environments for all.

Eco-friendly equipment is an easy way for foodservice facilities to make strides toward greener operations, as there’s a lot of affordable, accessible and high-quality equipment on the market.

When evaluating equipment options, buyers should educate themselves on the features and capabilities that will best help them achieve their operational, budget and green goals.

Green is the new black

Creating more sustainable and environmentally friendly designs doesn’t have to be a huge undertaking. Start small, focusing on little ways to drive big efficiencies.

In some circles, green practices, products and solutions carry a bit of a stigma. Often, people hear the word “green” and automatically think money. It is true. Purchasing greener equipment (or implementing greener practices) can require more of an upfront investment. It’s not always the most inexpensive option, at least initially.

However, what people often fail to consider is the long-term payoff, or lifetime return on investment, of earth-friendly solutions. While the upfront cost might be steeper, the savings generated over time pays off — big.

Get more sustainability content.

Did you enjoy this content? Click here to download an expansion on this content as a PDF, or enjoy the resources below:

- How to Squeeze More Value Out of Your Foodservice Equipment

- Where Does Sustainability Fit When Sanitation Comes First?

- How to Decrease Foodservice Food Waste

Contact a Hatco expert today.

To learn more about Hatco’s commitment to sustainability and all of the ways we can help designers reduce waste, conserve energy, minimize their carbon footprint, and save money, talk to your Hatco contact or find a local rep near you!